ZONESUN OFFICIAL STORE

ZONESUN ZS-EM300 Vacuum Mixing Emulsifying Machine

ZONESUN ZS-EM300 Vacuum Mixing Emulsifying Machine

Δεν ήταν δυνατή η φόρτωση της διαθεσιμότητας παραλαβής

DESCRIPTION

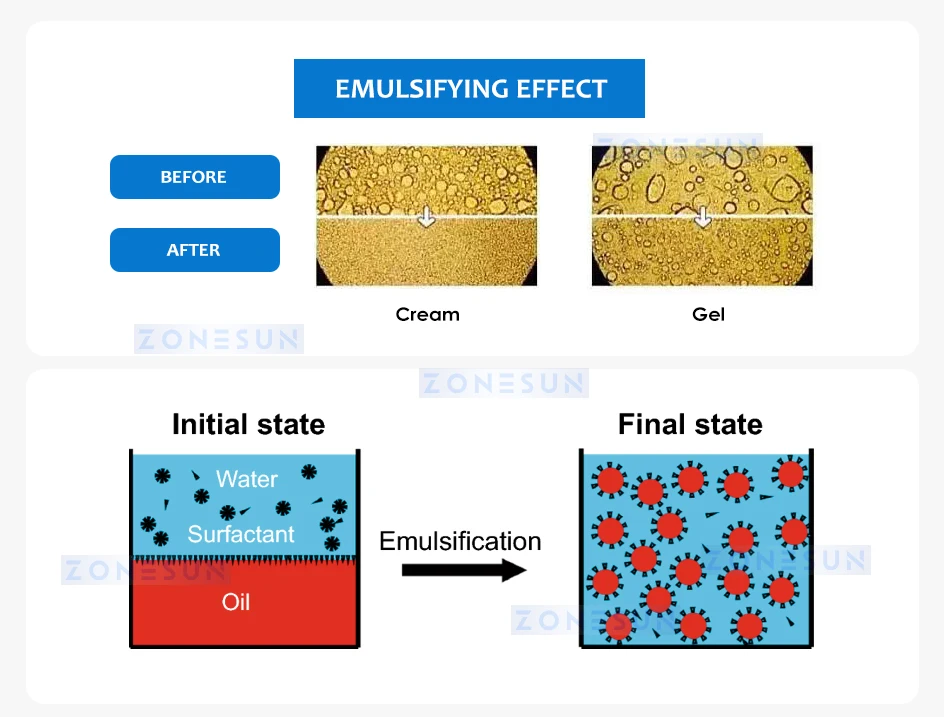

The ZONESUN ZS-EM300 Vacuum Mixing Emulsifying Machine is a complete system for producing stable emulsions, consisting of an emulsifying tank, a water tank, and an oil tank. Utilizing vacuum sealing technology, it prevents air incorporation and oxidation during processing. The emulsifying tank features a custom paddle and a high-shear homogenizer, delivering powerful mixing and consistent results. Ideal for cosmetics and food production, it ensures smooth textures, uniform blending, and long-lasting product stability.

PARAMETER

|

Model |

ZS-EM300 |

|

|

Emulsification Tank |

Volume |

300L |

|

Blending |

2.2kW, ≤63r/min |

|

|

Heating |

≤140℃, 18kW |

|

|

Homogenizer |

7.5kW, ≤3000r/m |

|

|

Oil Tank |

Volume |

100L |

|

Mixing |

750W, 1440r/m |

|

|

Heating |

≤140℃, 9kW |

|

|

Water Tank |

Volume |

240L |

|

Mixing |

750W, 1440r/m |

|

|

Heating |

≤140℃, 18kW |

|

|

Size |

Approx. 310*330*240cm |

|

PRODUCT DETAILS

MIXING PADDLE

Frequency conversion for speed regulation 0-62 r/min, the shape of the blades will be designed according to your materials.

HOMOGENIZER

Frequency conversion for speed regulation 0-3000r/min, high-speed shearing power, the materials are completely homogenized and mixed.

VACUUM SEALING

Defoaming during the vacuum mixing, meeting the requirements for the aseptic and high-standard products.

OIL-WATER TANKS

Pre-treatment System, 60% Water-soluble liquid and 40% oil-soluble liquid, pre-heat and disperse the raw materials, then transport them to main tank to begin emulsification.

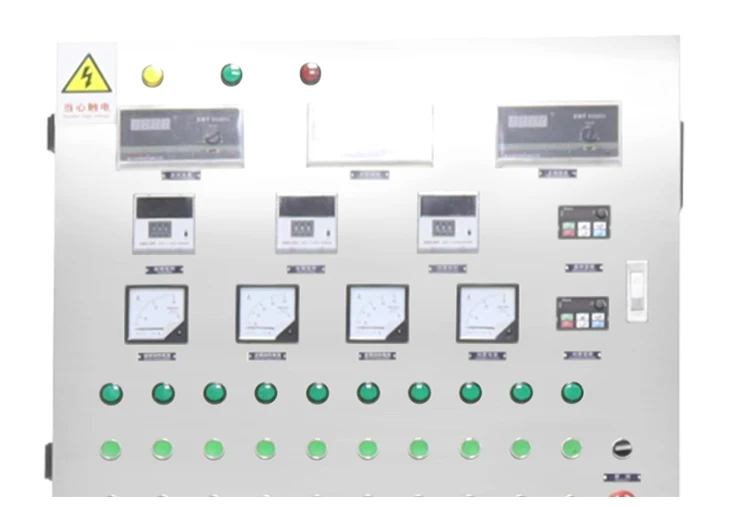

CONSOLE

The control panel displays and controls the equipment temperature, mixing, homogenization, pressure data, etc. in realtime.

ELECTRIX BOX

Internationally renowned brand components to ensure the quality of the equipment and longer service life.

Share